Case Study: Why a New Tile Roof in Superior Failed its City Inspection

By Captain Adam Nielsen | Published on May 15, 2024

The Mission

We were called to a property in Superior, CO, for an emergency second opinion. A different contractor was in the middle of a tile roof replacement when the project came to a screeching halt: the city inspector had failed their mid-roof inspection. The homeowner needed an expert to assess the situation and determine what went wrong.

Intel Gathered: Systemic Installation Failure

Our inspection revealed that the crew was not just making minor mistakes; they were fundamentally misunderstanding the roofing system they were installing. We identified numerous critical errors that guaranteed the roof would fail, including:

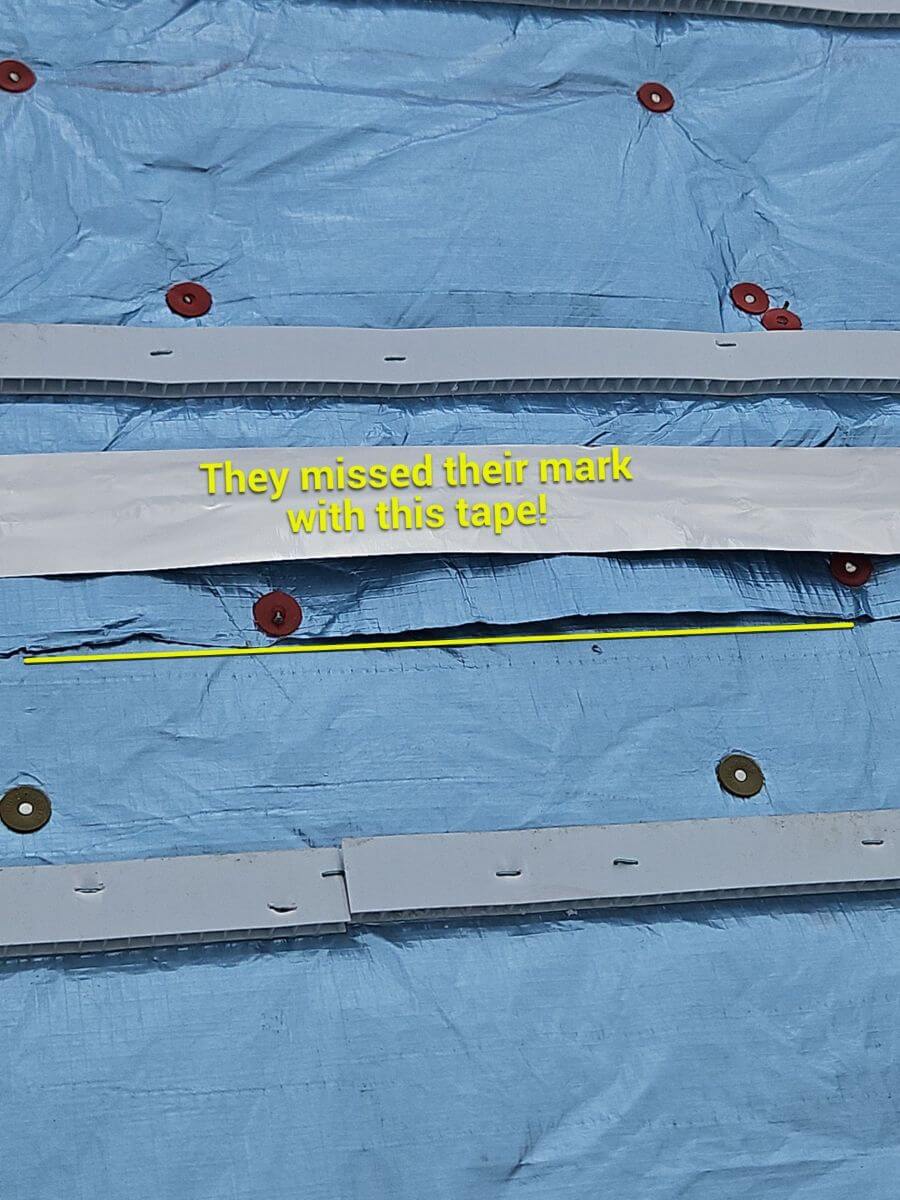

Failure Point 1: Improper Underlayment Installation

The vertical seams of the Sol-R-Skin underlayment were taped with 3" foil tape instead of the required 6" tape. Worse, the tape was often misaligned, completely missing the seam it was supposed to seal, rendering it useless as a watertight barrier.

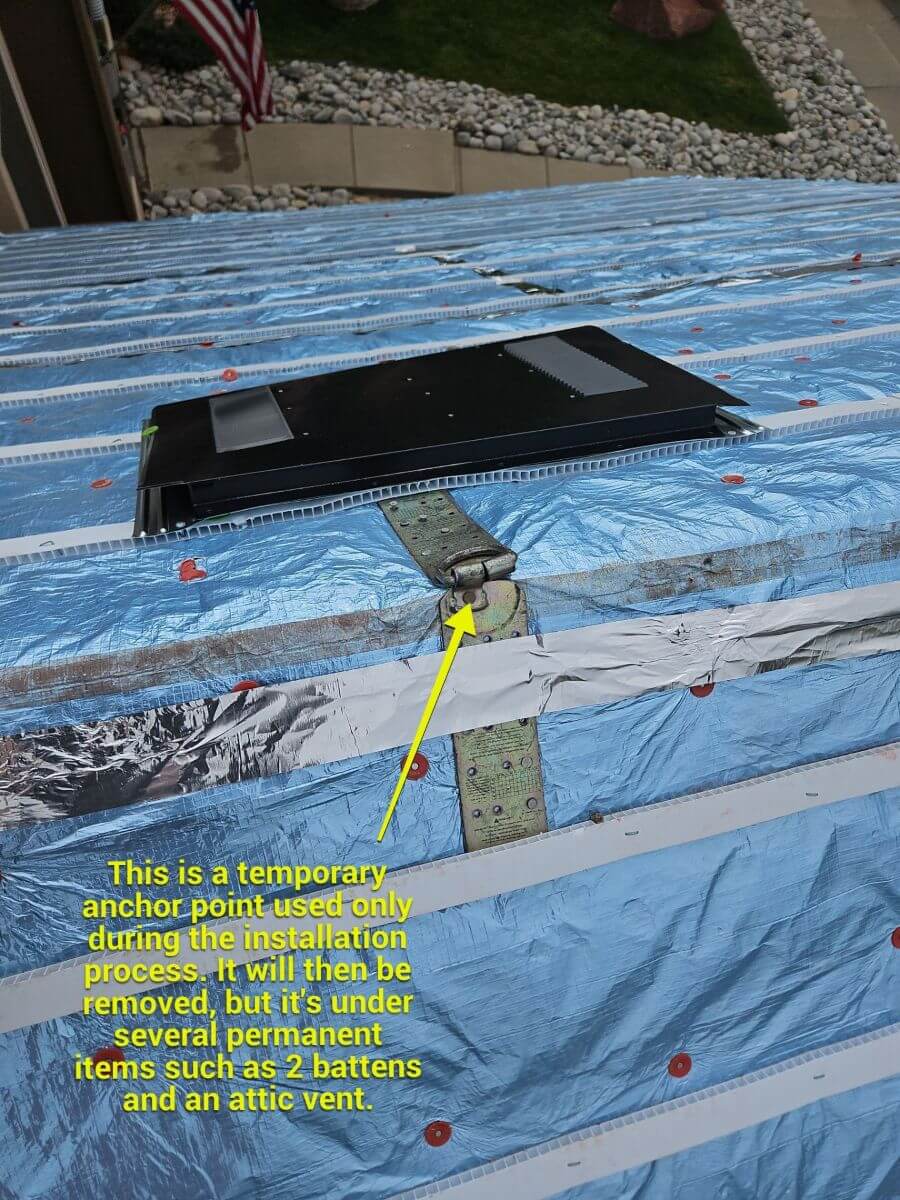

Failure Point 2: Gross Negligence with Equipment

In a shocking display of carelessness, the crew left a temporary safety harness anchor point installed *underneath* several permanent items, including two battens and an attic vent. This anchor, meant to be removed after installation, was now a permanent part of the roof assembly, creating a guaranteed point of failure and compromising the entire system.

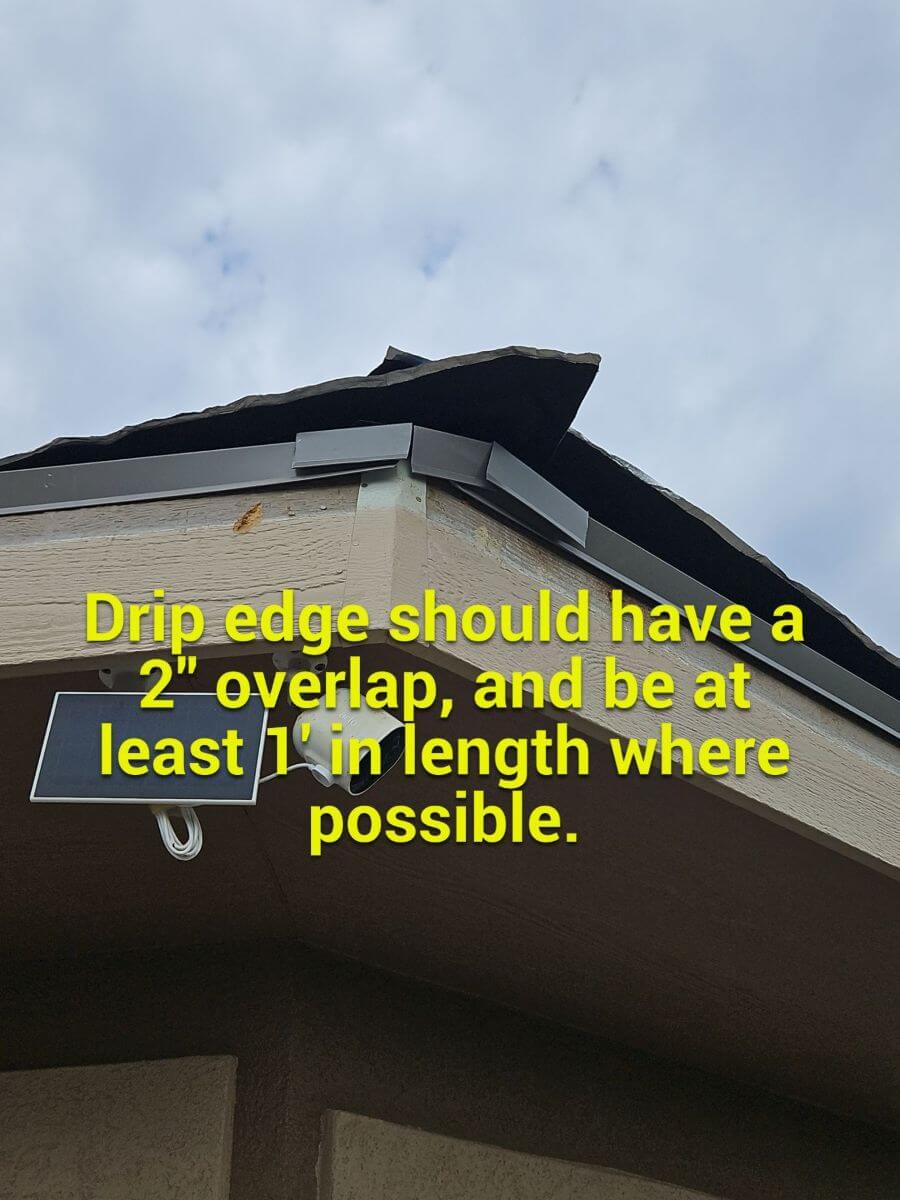

Failure Point 3: Incorrect Flashing & Edge Work

The crew demonstrated a clear lack of understanding of proper flashing techniques. The drip edge was installed with less than the required 2-inch overlap, creating gaps for water intrusion. In other areas, drip edge was omitted entirely at the rake edges—while not always required by code in Superior, it is an essential best practice that was ignored, preventing the tile from laying flat.

View the Original Field Report

This case study is based on the official second-opinion letter submitted to the homeowner. Download the full, declassified PDF to see the original intel.

Download Full Report (PDF)The Debrief

This failed inspection is a direct result of a "zombie roofer" crew attempting to install a complex system they didn't understand. They weren't following the manufacturer's installation guide or the local building codes, leading to an immediate halt in the project and a future filled with problems for the homeowner.

Complex systems like tile or metal require specialized expertise. If you have questions about your roofing project, join the largest Facebook group about roofing for non-roofers to ask people who have been through it before. Remember, a roof built to survive the apocalypse isn't just about using good materials; it's about expert installation. It's a no-Brainer!